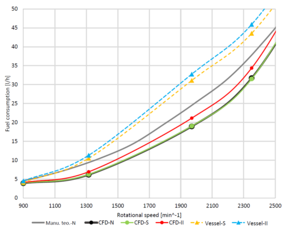

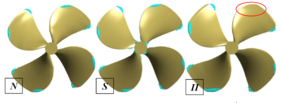

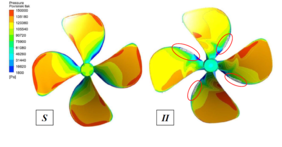

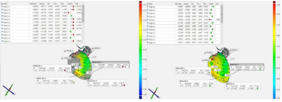

Work done in this paper covers preparations and construction of Computational Fluid Dynamics (CFD) analysis in need to observe the open water performance deviation as result of insufficient manufactured quality. Furthermore, we evaluate geometric influences on marine propeller performance regarding ISO 484 standard tolerance Classes. In addition, sizing effect of tetrahedral mesh is considered. With help of empirical calculations and convergence criterium we get sufficient mesh to work on. Considering all this, we define CFD experiment in equal definition for all tolerance Classes. At the end all obtained data is compared with real size experiment reference. Finally, connection between real and numerical experiment is made, for future anticipation in fuel consumption improvement.

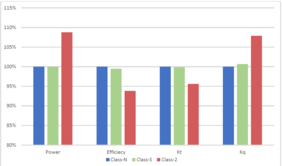

Despite the error concerning physical measurements and CFD final fuel data. CFD simulations have obviously been able to accurately predict fuel economy improvement among tolerance classes. Numerical CFD experiments have predicted an equal amount of percentage improvement as physical measurements did with different propeller geometries. In this case the intention was to predict relative fuel economy improvement, due to the improved geometry quality. This exact prediction is far more accurate than absolute prediction of fuel consumption in l/h. Both experiments showed a 4.6% relative improvement in fuel consumption due to a better tolerance class.

Therefore, we can conclude that numerical simulations were able to predict an accurate amount of improvement. Excessive error in consumed power is the result of various factors reducing calculation time. As justified, this error does not represent a concern, since the idea was to predict differences in fuel consumption and not predicting actual fuel consumption.